Posted on January 4th, 2024 by hpprocess

The frac sand market is booming, with the size reaching about USD 8.32 billion globally towards the end of ’22. Projections say that it can be expected to reach a value of almost USD 12.83 billion by 2028 at a CAGR of 7.50%.

The growth of this quartz sand mining can largely be attributed to its use as a proppant in the process of hydraulic fracturing in the oil industry, also referred to as fracking. The process is used to extract petroleum, natural gas, and other materials as a pressurized mixture accessible through drilling rock or land.

The two critical pieces of equipment used to dry frac sand are fluid bed dryers and rotary dryers. Before jumping into the frac sand drying technology, let us briefly overview fracking.

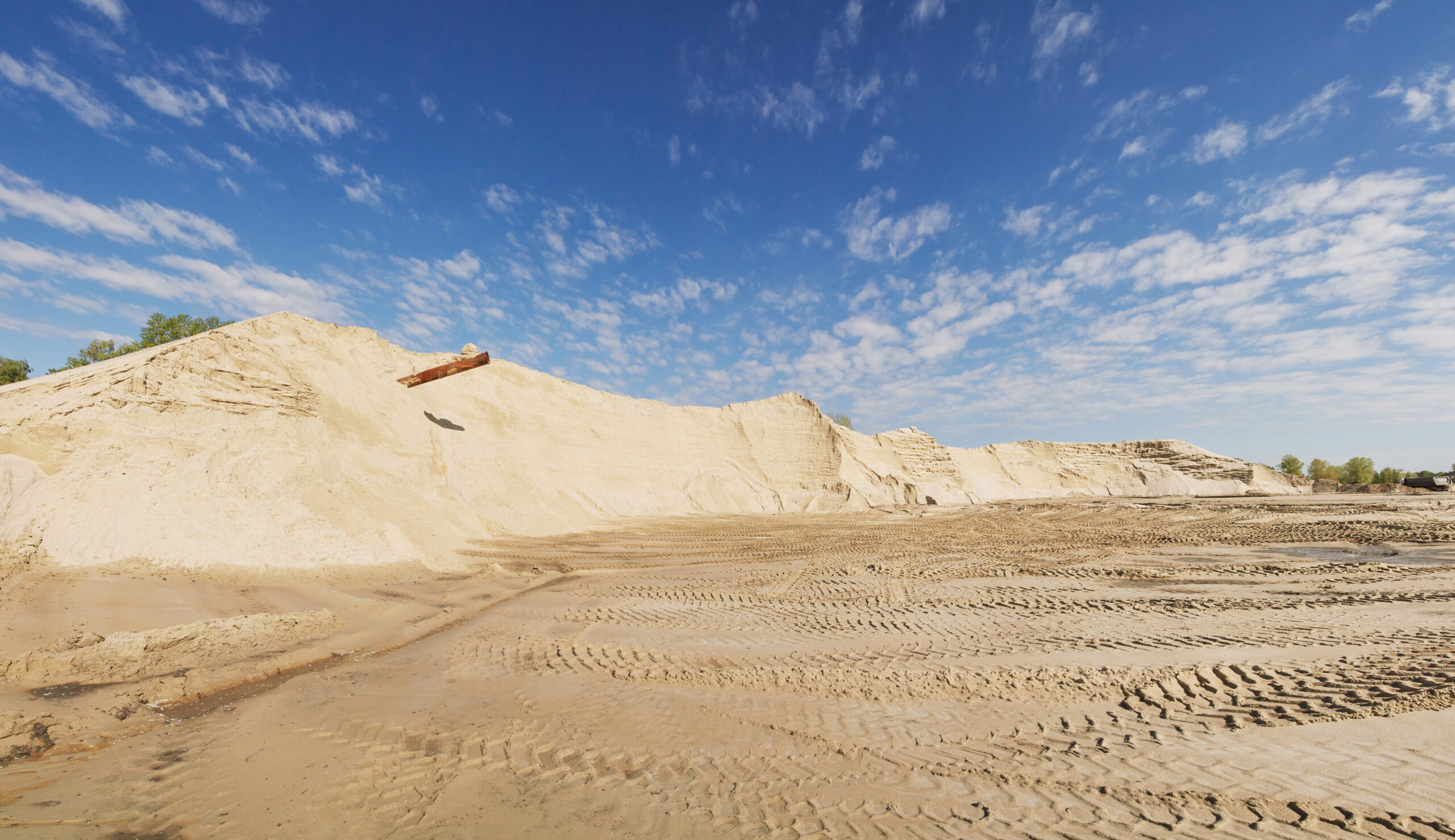

What is Frac Sand?

Frac sand is commonly known as a naturally occurring crystalline silica that can be extracted from pure sandstone. It is uniform and round with a size as small as a grain, which allows the fluids to be extracted to pass through.

Early usage of the frac sand was by the oil producers in the late 1860s, where it was used to stimulate shallow hard-rock wells. In the 1940s, it was further refined for application in water and gas wells, using the water and sand-based technique. The process was perfected for use in oil and gas wells as late as the 1990s with the advent of specialized frac sand.

How is Frac Sand Used?

The fundamental model for fracking methodology consists of a fluid, usually water, being pumped into the wellbore at a pressure higher than that of base rock formation and fracturing it.

It is possible to control the width of the fracture and the speed of the decline into the well by using frac sand as a proppant to prevent these fractures from prematurely closing as the pressure is removed.

Methods of Drying Frac Sand

American Petroleum Institute (API) defines the frac sand standards, including grain size, sphericity, crush resistance, and solubility. For the quality of sand to be acceptable, mining companies wash and dry it to remove any impurities.

Dryers can be used both at the start or the end of the fracking process, as long as they happen before their transportation to the job site. Let us look at the two most common frac sand drying technologies.

Rotary Dryers

A rotary dryer is a horizontally inclined rotating cylinder that allows the wet feed material and heated air to enter from one end and pass through to the other. The rotating cylinder uses neutral to slightly negative pressure and is sealed to stationary breechings or end boxes at both ends.

The breechings are connected to the cylinder using various seal configurations and can be sealed to any stationary downstream equipment, such as the air heater or off-gas handling equipment.

Fluid-bed dryers

Fluid-bed dryer uses a high heat transfer rate by suspending the sand in drying air. Thus, the sand is completely surrounded by the drying gas or air, causing the material to act like a liquid. This process causes the sand to act like a liquid, producing a high heat transfer rate. It is easier and cheaper to maintain since no moving parts are involved.

Pick What Works Best for You

The frac sand industry uses both dryers depending on the specific needs. A fluid bed dryer is better suited for consistent needs, while a rotary dryer allows greater process turndown capability. If your throughput, particle size, and moisture remain the same, you should opt for fluid bed drying. The rotary dryer provides more versatility with the material properties.

Heyl Patterson offers a range of high-efficiency industrial dryers, both fluid bed dryers and rotary dryers that can handle a broad range of materials.

Looking to acquire the right technology for the drying process? Find the best technologies and equipment at our pilot plant testing lab.

Contact us to learn more.