Posted on December 28th, 2023 by hpprocess

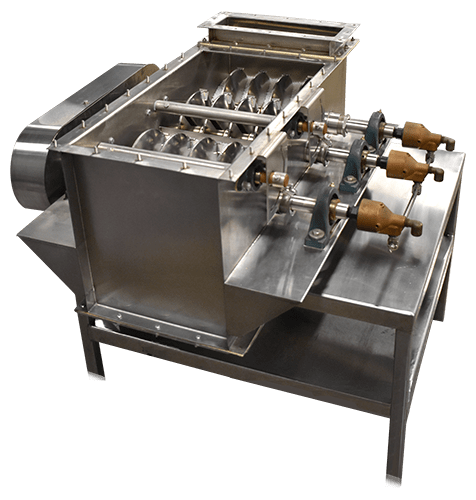

Heyl Patterson is a trusted name in the thermal processing solutions industry. This blog focuses on the standout features of Heyl Patterson MultiDisc thermal processors and the available custom options. These processors are engineered for efficient heat transfer during the drying, heating, and cooling process of bulk solids, offering both efficiency and cost-effectiveness.

Keep reading to find out about what sets these processors apart.

Unique Features of MultiDisc Thermal Processors

Regarding thermal processing, the heat transfer method is a game-changer. MultiDisc Thermal Processors employ a conduction-convection heat transfer approach. This indirect method is highly efficient, especially considering the high product-to-surface area ratio. It minimizes off-gas volumes, making it a much more clean option.

Key Design Elements

- High Product-to-Surface Ratio: This feature enhances heat transfer efficiency, making the unit more effective in its core functions.

- Versatile Fluid Circulation: You can choose how the heat transfer fluids circulate in a series or parallel flow patterns. This type of adaptability allows for more customized operations.

- Compact Size: The processor’s small footprint doesn’t compromise its processing capacity. It can function in a space that barely fits similar units’ drive train.

These design elements collectively reduce operational costs. For instance, the design minimizes surface fouling and power consumption. So, you’re not just getting a machine that does its job well; you’re also getting one that does it economically.

Typical Industries & Applications

This processor is versatile and can be used for a wide range of industrial applications, including agriculture, ceramics, chemicals, and more. Whether you’re in the food, metal, or automobile industry, this unit has applications that can optimize your manufacturing process like no other.

These features aren’t just nice but imperative in the manufacturing industry, where efficiency and cost-effectiveness are paramount.

Let’s now understand how users can customize these processors to fulfill specific requirements.

Customization through Lab Testing

Customization compliments the overall quality of the product by empowering the thermal processing unit. That’s where the CPEG Test Lab comes in. This 15,000-square-foot facility offers a range of tests designed to adapt MultiDisc thermal processors to your specific requirements.

How does the Lab Customize Processors?

- Pilot-Scale Testing: By simulating real-world conditions, the lab identifies the best configurations for your processor, ensuring it meets your operational needs.

- Field Testing: For those unique scenarios where in-house testing isn’t enough, field tests ensure the processor can adapt to your specific environmental conditions.

- Data Analysis: The lab uses advanced diagnostic tools to analyze test results, which are then used to fine-tune the processor’s settings and features.

Why Customization Matters

- Material Compatibility: The lab tests confirm that the processor can handle a variety of materials, making it versatile for different industries like chemicals, food, and more.

- Operational Efficiency: Data from the lab is used to optimize the processor’s design, improving its efficiency and reducing operational costs.

The lab also offers on-site visits, allowing you to witness the test process. All tests are conducted under strict confidentiality agreements to protect any information on your personalized product.

Enhance Your Operations with MultiDisc Thermal Processors

We’ve just learned how MultiDisc thermal processors deliver efficiency and adaptability. Our engineered design elements cut operational costs without compromising performance. The CPEG Test Lab adds another layer of customization, ensuring each unit is precisely tuned to your operational needs.

If a customized thermal processing solution is what you’re after, reach out to us. Contact us to explore how we can enhance your operations.