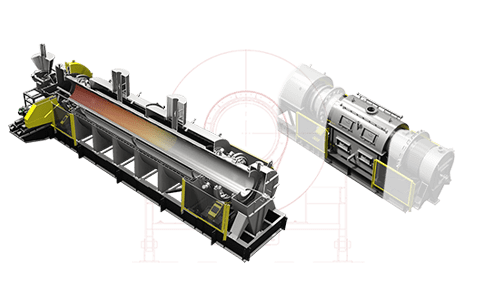

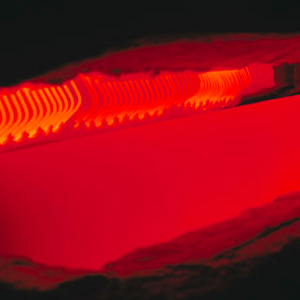

Heyl Patterson’s rotary calciners provide efficient processing of minerals used to manufacture lithium-ion batteries. From minerals used in anodes such as metallic-lithium, natural and artificial graphite, activated carbon, carbon black, lithium titanate, tin-based alloys, and silicon-based materials, to materials used in cathodes such as oxides of lithium manganese, lithium cobalt, and nickel cobalt, lithium-ion phosphate, and electronic conducting polymers, Heyl Patterson’s rotary calciners provide high-temperature processing in a controlled environment.

Rotary Calciner Features & Benefits:

- Custom sizes

- High-temperature enclosed shell design

- Inert, oxidizing, reducing, or dehumidifier process atmospheres

- Co-current and counter-current material/gas flow designs

- Multiple heating zone configurations

- Plug flow operation for product uniformity

- Integral coolers

- Adjustable retention time

- Recuperative or regenerative burner systems prevent overheating

- Accurate bed temperature control with wireless telemetry for improved processing

- Custom-designed internal shell components provide maximum heat and mass transfer

- Innovative seal designs for hazard mitigation

Discuss a project?

Minerals Testing

Test a variety of minerals with a Heyl Patterson rotary calciner at our state-of-the-art test facility. Multistep and multistage testing with additional CPEG test equipment can be conducted to help validate equipment and processes.